Autoclaved Aerated Concrete (AAC)

Our products has been awarded with Green Label Certificate, Singapore Green Building Product Certificate and has met/ exceeded project requirements by BCA/ HDB/ LTA/ SCDF(Fire Rated Systems).

Our manufacturer in Malaysia aims to deliver quality products to its customers. They have invested in state-of-the-art machineries and technology supplied by Wehrhahn of Germany.

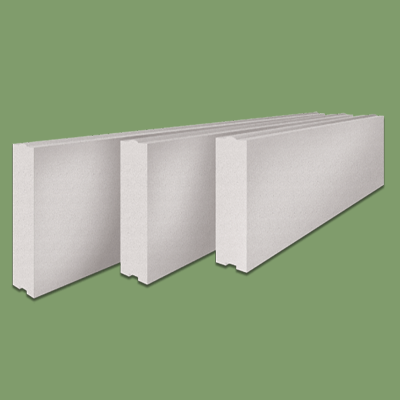

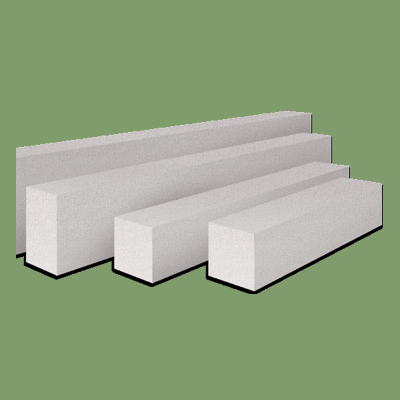

Situated at Serendah, Selangor. The production facility manufactures blocks efficiently and engineered panels cost-effectively with an annual capacity of 975,000 cubic meters. It covers a wide range of AAC products with various compressive strengths to cater for specific architectural and design requirements of various types of buildings. The main products include AAC blocks, panels and lintels with dry density of 450 kg/m³ – 820 kg/m³.

With its storage capacity of more than 10,000 m², the supply of AAC products will always be sufficient to meet the demand of on-going projects.

Advantages

Cost-effective

AAC Panels are lightweight and easy-processed, which may ease labour intensity.

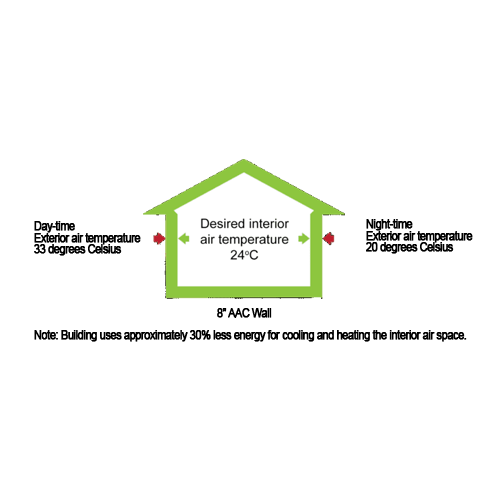

Thermal Comfort & Energy Saving

AAC panels are composed of many small holes, which are independent and in order.

Lightweight

High porosity of AAC panels can reduce the bulk density of materials.

Eco-friendly

AAC panels can be recycled after the wall removal without environmental pollution

Dimensional Accuracy

Our AAC products are of precise sizes and the tolerance of length, height and width is +1.0mm.

Durable

AAC panel is masoned by special mortar whose thickness is only 3mm, so cracking possibility of the gap is greatly lowered

Sound Resistant

ALC panel has dual nature, sound absorption and sound resistance, which other building materials do not have.

Impact Resistant

Reinforcing bar in the panels perform stabilized, toughening and impact resistance functions

Good Workability

They are easy to groove and do not need much time spent in cutting.

Water Resistant

AAC panels contain millions of closed microscopic cells which strongly resist moisture from passing through.

Fire Resistant

A 15cm-thick wall can resist fire for as long as 4 hours.

Autoclaved Aerated Concrete

Benefits

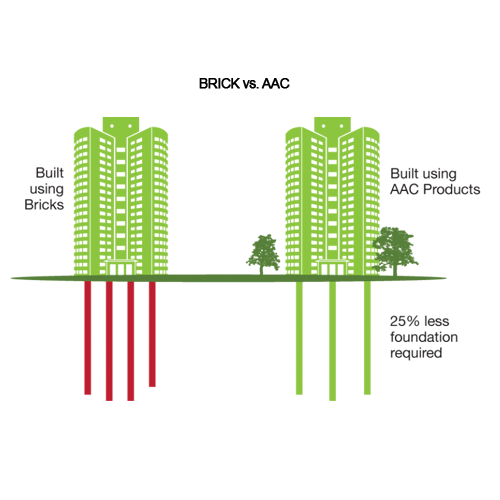

Save up to 25% of

Foundation Cost

25% less foundation required

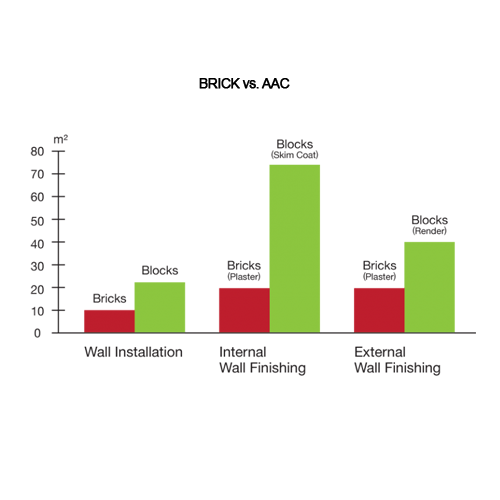

Wall Installation

Speed

Thermal Control

Manpower Efficiency

Production Process

AAC products are made using slurry mix containing cement, sand, lime and aerating agent. The slurry is poured and moulded to form lightweight blocks, panels and lintels upon which are cured in autoclave.

Where to use AAC?

Autoclaved Aerated Concrete is ideal for load-bearing Adhesive.

and non-load bearing applications.

Residential Units

Commercial Units

Hospitals

Factories

Schools / Universities

Hotels

Shopping Malls

Public Transport

Intersection Buildings